Fired Heater Oil Refinery

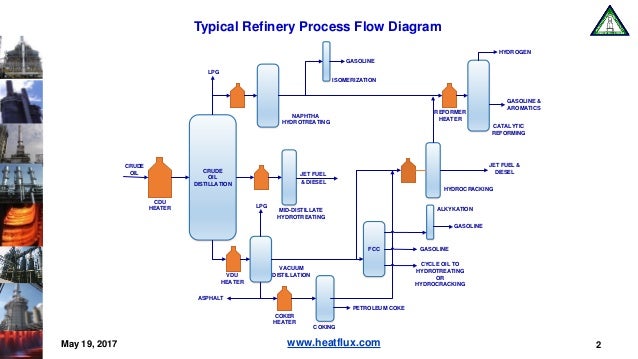

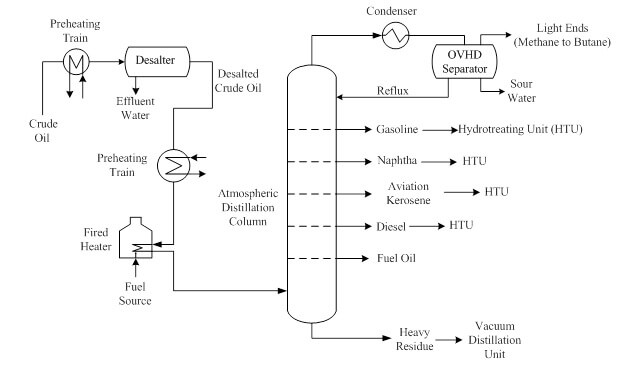

Operating a refinery uses a huge amount of energy.

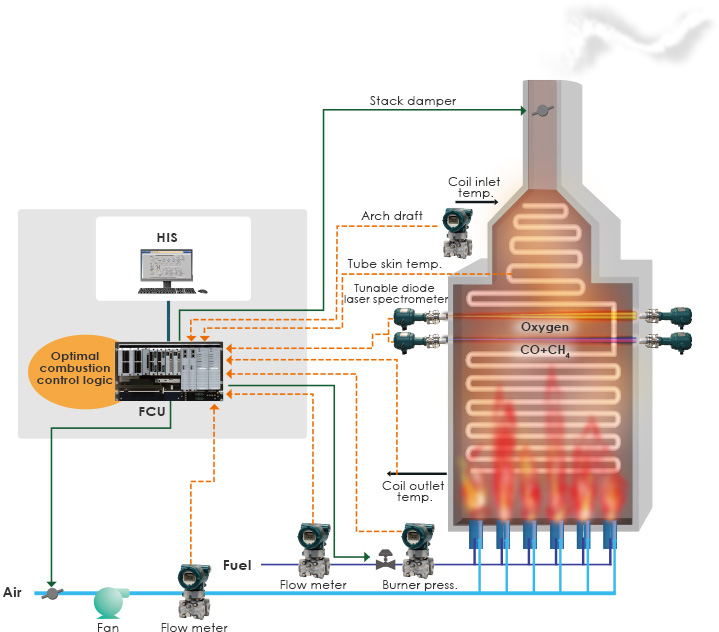

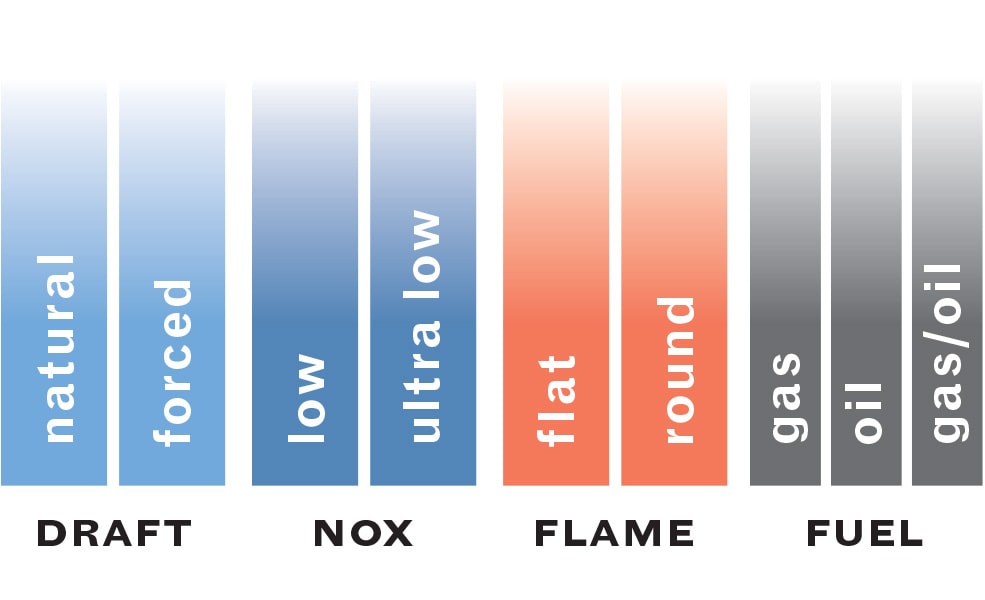

Fired heater oil refinery. Fired heaters are one of the most important equipment in any refinery or petrochemical plant. Optimize furnace efficiency with reliable real time data. Structural configuration radiant tube coil configuration and burner arrangement. Ensuring the efficient and safe performance of your fired heaters can be challenging and worker safety fuel costs asset health issues and potential emissions are always a concern.

Design manufacturing supply and construction of fired heaters designed to api 560 or other international standards is the core of our business. Even a small savings in fired heater fuel can provide large cost savings to refineries. Our process furnace manufacturing capability includes alloy coil materials and certified weld procedures are registered for the required weld processes. The majority of fire heaters are designed using the api 560 for general refinery services which is the industry standard for designing many fire heaters in the oil and petrochemical industry.

Electric immersion heaters are a cost effective and efficient way to heat crude oil safely. As a process heating company we manufacture to api standard 560 fired heaters for general refinery service. They also are used to maintain the target temperature for lubrication oils while in storage. This is a crucial step before the fractional distillation process.

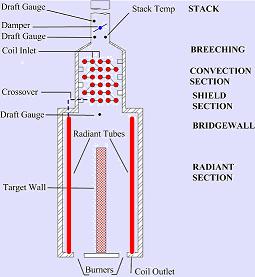

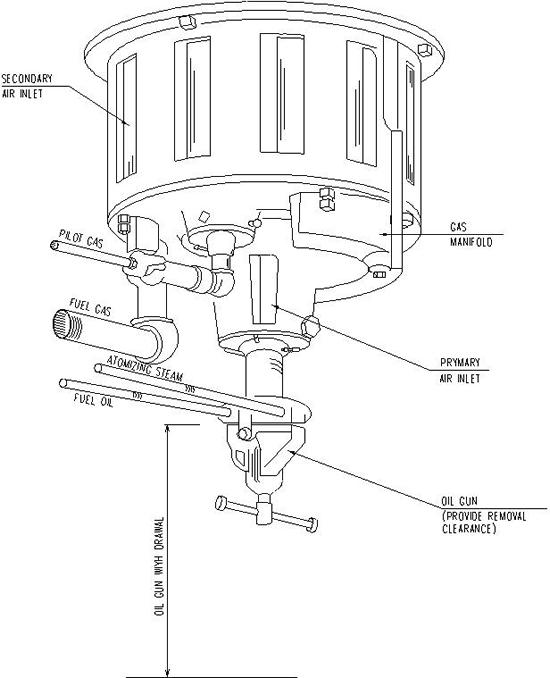

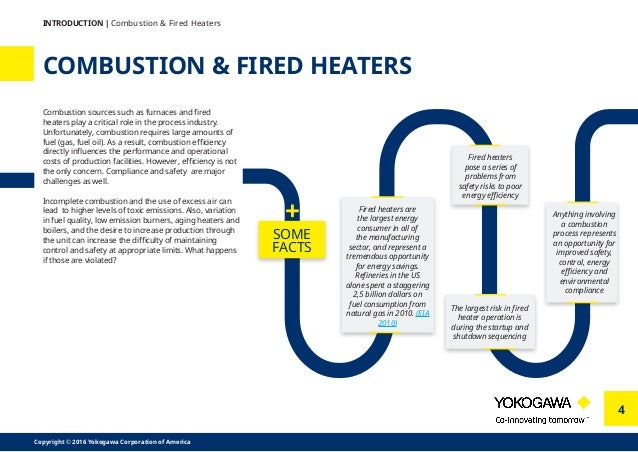

The type of heater is normally described by the. Fired heaters are insulated enclosures that are heated internally by a series of burners to heat fluids flowing inside the tubes. A fired heater is an insulated enclosure that uses the heat created by the combustion of fuels to heat fluids contained inside coils. Also heaters are one of the largest consumers of fuel in the refinery and minor improvements in fuel consumption of the fired heaters can lead to quite large savings.

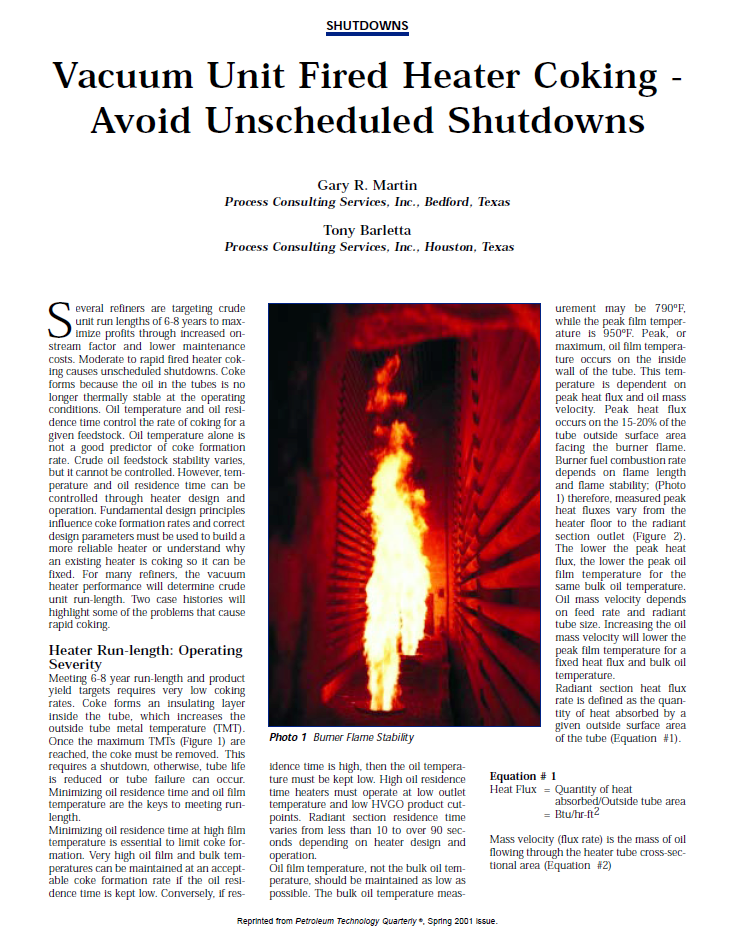

A fired heater is essentially a refractory lined box containing metal tubes through which process fluids pass. A leading fired heater manufacturing company esteem is a leading epc company serving the hydrocarbon and chemical industries spanning oil gas petrochemical refining fertilizer and related sectors. Fired heaters designed for refinery applications are generally designed for allowable average radiant heat flux q r which is one of the most closely watched design factors of fired heaters for given process application. Processes tend to be endothermic requiring the input of heat energy to initiate or maintain chemical processing.

Reduce fuel costs without shortening the operating life of your fired heaters.